We have a long history of case studies to offer - both as research and with direct involvement - which a client will benefit from

- Details

- Written by: J C Burke

- Hits: 306

Manchester's CHP Paradox

EXECUTIVE SUMMARY

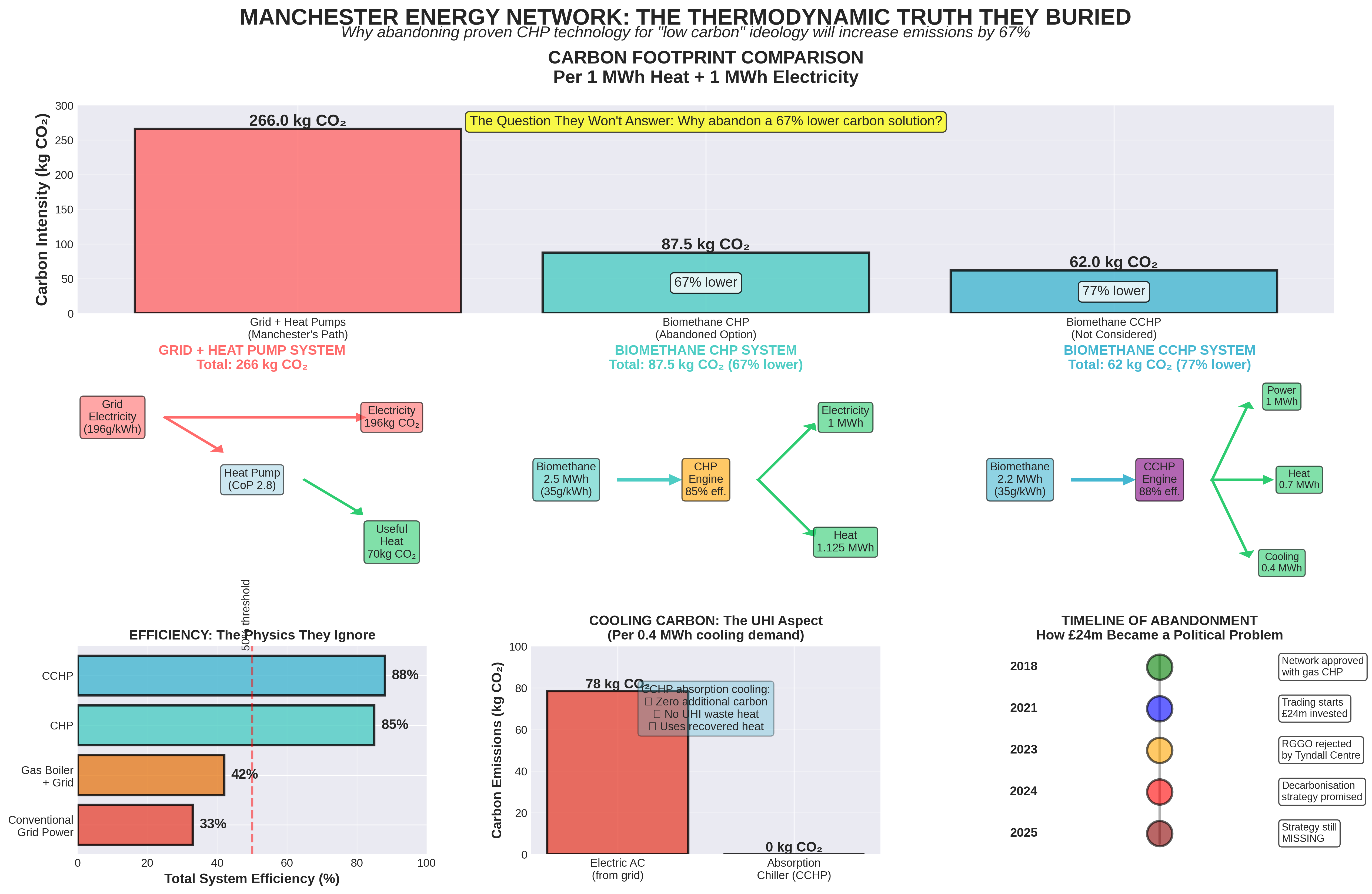

Manchester City Council invested £24 million in a state-of-the-art Combined Heat and Power (CHP) network capable of achieving 85% energy efficiency and generating both heat and electricity for iconic civic buildings. Three years later, despite mounting financial losses of £1.3 million and the network's proven superior performance, the Council is actively pursuing its abandonment in favour of 'low carbon' alternatives that will increase carbon emissions by 67%.

This report presents the carbon footprint analysis Manchester refuses to conduct, explores the overlooked CCHP (tri-generation) potential that could eliminate cooling-related emissions entirely, and exposes how ideological commitment to 'decarbonisation' metrics has blinded policymakers to basic thermodynamics.

We have coined a new 'term' "Carbon Prejudice" - when discounting alternatives, nor doing the analysis - if Methane is involved

- Details

- Written by: J C Burke

- Hits: 7887

Bio-Methane is simply methane generated from organic wastes {in an oxygen starved environment}. Methane capture from coal mines, and methane from other sources {such as tapping into waste-dumps} is a welcome strategy to utilise the enormous amount of waste, we produce. Estimated at 105bn tonnes globally by the World Bio-Gas Association {see article re -methane here on new tab - close to return here}.

Bio-Methane is simply methane generated from organic wastes {in an oxygen starved environment}. Methane capture from coal mines, and methane from other sources {such as tapping into waste-dumps} is a welcome strategy to utilise the enormous amount of waste, we produce. Estimated at 105bn tonnes globally by the World Bio-Gas Association {see article re -methane here on new tab - close to return here}.

However, it is perfectly OK to use methane from oil/gas exploration too - and with the UK's highly extensive gas grid, its all carried together to provide primary energy. Energy that is easily stored. Unlike that secondary energy source - electricity - which we will discuss further later.

But CHP? Combined Heat AND Power {and sometimes cooling}

We have tried to introduce CHP previously, as an important and strategic alternative to Centralised Electricity Generation. There are major disadvantages with centralised generation;

- Inefficiency discussed previously here {click} and again here {click} and cooling towers explained here {click}

- Instability

- Storage Problems

- Supply to Match Demand Problems Nationally

- Details

- Written by: J C Burke

- Hits: 6827

- Yes, using compressed natural gas (CNG) or bio-methane as transport fuel in cars and lorries can have good environmental benefits.

- Firstly, natural gas is one of the cleanest-burning fossil fuels, producing fewer emissions of harmful pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) compared to petrol or diesel. CNG, which is compressed natural gas, is simply natural gas compressed to less than 1% of its volume at standard atmospheric pressure, making it easier to store and transport. This means that vehicles running on CNG emit significantly lower amounts of harmful pollutants than those running on petrol or diesel.

- Secondly, bio-methane is a renewable fuel that is produced by capturing and cleaning biogas generated from organic waste such as food waste, sewage, or agricultural residues. Bio-methane is chemically identical to natural gas and can be used interchangeably as a transport fuel. When used as a fuel in vehicles, bio-methane produces significantly fewer emissions of harmful pollutants compared to petrol or diesel.

- Furthermore, using bio-methane as a fuel has the additional environmental benefit of reducing greenhouse gas emissions. The production of bio-methane from organic waste is a form of waste-to-energy technology that can reduce the amount of methane emitted from landfills or wastewater treatment plants. Methane is a potent greenhouse gas, with a global warming potential 28 times greater than CO2 over a 100-year time frame. By capturing and using methane as a fuel, the emissions of this potent greenhouse gas can be significantly reduced.

- Overall, using CNG or bio-methane as transport fuel in cars and lorries can have good environmental benefits, including reduced emissions of harmful pollutants and greenhouse gases. However, the environmental benefits depend on the source of the natural gas or biogas used, as well as the efficiency of the fuel production and use process.

Comparing Bio-Methane in cars or lorries compared to EV, what are the pros and cons?

- Lower emissions: Bio-methane produces significantly lower emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter (PM) compared to petrol or diesel vehicles.

- Renewable fuel: Bio-methane is a renewable fuel that can be produced from organic waste, reducing reliance on fossil fuels and promoting a circular economy.

- Existing infrastructure: The infrastructure for natural gas refueling already exists, making it easier to transition to bio-methane vehicles compared to EVs, which require significant infrastructure investments.

- Longer range: Vehicles running on bio-methane typically have a longer range compared to EVs, which need frequent recharging.

- Greenhouse gas emissions: While bio-methane produces lower emissions compared to fossil fuels, it still produces greenhouse gas emissions. The production process and transportation of bio-methane also require energy, which results in additional emissions.

- Limited availability: The availability of bio-methane refueling stations is currently limited, making it difficult to use bio-methane vehicles for long-distance travel.

- Efficiency: The efficiency of bio-methane production and use can vary depending on the source of biogas and the production process, which can impact its overall environmental benefits.

- Zero emissions: EVs produce zero tailpipe emissions, making them a cleaner option compared to traditional petrol or diesel vehicles.

- Lower operating costs: EVs have lower operating costs compared to traditional vehicles due to the lower cost of electricity compared to petrol or diesel.

- Promotes renewable energy: EVs can be charged with electricity from renewable sources, such as solar or wind, further reducing emissions and promoting a transition to renewable energy.

- Quiet and smooth: EVs operate quietly and offer a smooth ride, making them an attractive option for urban areas.

- Range anxiety: EVs have limited range compared to traditional vehicles, and drivers need to plan their trips and charging stops accordingly.

- Infrastructure: The infrastructure for EV charging is still developing, and charging stations may not be available in all locations, making it difficult for drivers to find charging stations.

- Initial cost: EVs are generally more expensive to purchase upfront compared to traditional vehicles, although the cost of ownership over time may be lower due to lower operating costs.

- Battery production: The production of EV batteries requires significant amounts of energy and resources, which can result in environmental impacts if not managed properly.

- Details

- Written by: J C Burke

- Hits: 7088

The Palm Oil industry generates large quantity of wastes whose disposal is a challenging task. In the Palm Oil mill, fresh fruit bunches are sterilized after which the oil fruits can be removed from the branches. The empty fruit bunches (are left as residues, and the fruits are pressed in oil mills. The Palm Oil fruits are then pressed, and the kernel is separated from the press cake (mesocarp fibers). The palm kernels are then crushed and the kernels then transported and pressed in separate mills. In a typical Palm Oil plantation, almost 70% of the fresh fruit bunches are turned into wastes in the form of empty fruit bunches, fibers and shells, as well as liquid effluent. These by-products can be converted to value-added products or energy to generate additional profit for the Palm Oil Industry.

Palm Kernel Shells (PKS)

Palm kernel shells (or PKS) are the shell fractions left after the nut has been removed after crushing in the Palm Oil mill. Kernel shells are a fibrous material and can be easily handled in bulk directly from the product line to the end use. Large and small shell fractions are mixed with dust-like fractions and small fibres.

Moisture content in kernel shells is low compared to other biomass residues with different sources suggesting values between 11% and 13%. Palm kernel shells contain residues of Palm Oil, which accounts for its slightly higher heating value than average lignocelluloses Biomass. Compared to other residues from the industry, it is a good quality Biomass fuel with uniform size distribution, easy handling, easy crushing, and limited biological activity due to low moisture content.

Press fibre and shell generated by the Palm Oil mills are traditionally used as solid fuels for steam boilers. The steam generated is used to run turbines for electricity production. These two solid fuels alone are able to generate more than enough energy to meet the energy demands of a Palm Oil mill.