We have a wide range of ongoing projects and policies to impliment - some modest, others on a National scale

- Details

- Written by: Lenovo

- Hits: 3565

Lenovo ThinkSystem N1380 Neptune Chassis

Lenovo ThinkSystem N1380 Neptune Chassis

Empowering Exascale to Everyscale™: Your Foundation for a Lenovo Neptune HPC or AI Supercomputer.

Datasheet

“Moving from air cooling to Lenovo Neptune® liquid cooling, our cluster delivers four-times greater performance than our previous infrastructure within the same physical footprint, increasing our processing power so we can run cutting-edge research faster.”

- Scott Yockel, University Research Computing Officer, Harvard University

Exascale technology, industry standard footprint

As the demand for more powerful applications like AI has skyrocketed, data centers have grown more crowded, hotter and consume more energy. Lenovo’s next generation of Neptune liquid cooling technologies was designed to address those challenges. The ThinkSystem N1380 Neptune chassis is the core building block, built to enable exascale-level performance while maintaining a standard 19-inch rack footprint. The ThinkSystem N1380 Neptune chassis uses liquid cooling to remove heat and increase performance and is engineered for the next decade of computational technology.

Lenovo Neptune® is the foundation of the Lenovo N1380 Neptune® introducing a new generation of the longest proven, most advanced, direct and warm water cooling available in the industry. An innovative Power delivery and distribution design around a patented integrated Power Conversion Station enables broadest data center compatibility. And finally, the formfactor itself was engineered from ground up to provide the additional space needed without breaking the data center standards while maintaining the scalability for customers of every size.

The next cool era of Lenovo Neptune

Since 2012, Lenovo’s direct water-cooling has consistently led the industry with advanced cooling innovations. Our dedication to quality-engineering and performance-design is demonstrated by over a decade of delivering reliable water-cooled solutions worldwide.

Lenovo Neptune® utilizes superior materials, including custom copper water loops and patented CPU cold plates, for full system water-cooling. Unlike systems that use lower reliability FEP plastic, Neptune® features durable stainless steel and reliable EPDM hoses. N1380 features an integrated manifold that offers a patented blind-mate mechanism with aerospace-grade drip-less connectors to the compute trays, ensuring safe and seamless operation.

Neptune® is designed to operate at water inlet temperatures as low as the dew point allows, up to 45°C. This design eliminates the need for additional chilling and allows for efficient reuse of the generated heat energy in building heating or adsorption cold water generation. It uses water as a coolant, a much safer and more efficient alternative to the commonly used PG25 Glycol liquid, reflecting our commitment to environmental responsibility.

The unique design of the N1380 eliminates the need for internal airflow and power-consuming fans. As a result, it achieves a reduction in typical data center power consumption by up to 40% compared to similar air-cooled systems.

With great power comes great performance

Today, processors are drawing several hundred Watts of power and accelerators are surpassing a Kilowatt. The Lenovo ThinkSystem N1380 features a cutting-edge power subsystem designed to support the most power-demanding compute and acceleration platforms for the next decade.

This newly developed feature incorporates up to four ThinkSystem 15kW Titanium Power Conversion Stations (PCS). These stations supply power to an internal 48V busbar, which in turn powers the compute trays. The PCS design is a game-changer, merging power conversion, rectification, and distribution into a single package. This is a significant transformation from traditional setups that require separate rack PDUs, additional cables and server power supplies, resulting in best-in-class efficiency.

With four PCS units supporting N+1 operation and 120% oversubscription, the total power capacity for the enclosure reaches 54kW DC. Given a 96% peak AC/DC conversion efficiency and an almost perfect Power Factor at 99% above 50% load, the total apparent power is 58 kVA. When you place three enclosures in a Rack Cabinet, you achieve a total power density of 162kW DC or ~175kVA. This configuration enables the highest performing technologies in a compact package.

The 48V busbar enhances system-level efficiency, reducing efficiency loss by up to 7% through streamlined power delivery. Also, for a given power level, operating at 48V reduces power losses by 16x compared for state-of-the-art high-performance components that operate natively at 48V to delivering the same power at 12V, while still efficiently transforming down to 12V.

The advanced design of the N1380 power subsystem promises a decade of top-tier performance in a streamlined package.

A scalable championing of industry standards

The escalating power capacity, cooling demands, and the growing size of server components present a unique challenge in packaging solutions. The Lenovo ThinkSystem N1380 Neptune turns these challenges into opportunities. Instead of resorting to specialized rack-level form factors, the N1380 is ingeniously designed to conform to industry and data center standards. This design philosophy ensures it supports customers of every scale, across the globe, in their unique environments.

The design of the Lenovo ThinkSystem N1380 Neptune streamlines complex infrastructure management by integrating key components such as power routing with a busbar and water distribution through an internal manifold. It can seamlessly connect to standard data center CDUs – whether they are in-rack, row-level, or data center-level – without necessitating customization.

It also includes a System Management Module (SMM3) that connects directly to every server Base Management Chip (BMC) for out of band system management. That reduces massively the cable requirements for a management network, with a single or redundant connection to the N1380 serving all the servers within.

Each 13U Lenovo ThinkSystem N1380 Neptune houses up to eight Lenovo ThinkSystem SC-Series Neptune trays, strategically positioned vertically. This configuration translates the height of the N1380 into a 21’ width for the compute trays, aligning closely with the Open Compute (OCP) form factor. This design not only optimizes space but also ensures compatibility for a future steered by HyperScale and Cloud Service Provider direction.

Up to three N1380 enclosures can fit into a standard 19’ rack cabinet, packing 24 SC-Series trays into just two 60x60 data center floor tiles or – including rack extensions – on less than a square-meter / ten square-feet. From there, you can scale multiple racks, full rack rows, or data center level ExaScale deployments. The N1380 offers a truly modular and scalable solution for Supercomputing, from ExaScale to EveryScale™.

Specifications

| Form Factor | 13U Enclosure (N1380) designed for 19” rack cabinets: Up to 3 enclosures per rack |

| Technologies | Compatible with ThinkSystem SC-Series Supports general purpose and acceleration compute technologies from Intel, AMD, & NVIDIA |

| Current Available Computer Types | Lenovo ThinkSystem SC750 V4 SC750 V4 datasheet |

| Power Management | Advanced power monitoring, management, and power capping capabilities via Lenovo XClarity Energy Manager (LXEM) or Confluent open-source software, paired with Energy Aware Runtime (EAR) for energy optimization |

| Systems Management | Features System Management Module (SMM3) in the enclosure, supports daisy chaining and BMC pass-through, integrates with Lenovo XClarity and Confluent. |

| Front Access | Compute trays, Cable Management |

| Rear Access | Water connection, Power and System Management Module (SMM3) 2x RJ45 on the SMM for XCC with daisy chain support, USB Type A for SMM FFDC log collection |

| Power Supply | Accommodates up to 4x HS 15kW Titanium Power Conversion Stations (PCS) with fully balanced phases, N+1 redundancy. Each PCS providing a 32A 380-480V – or two PCS sharing a 63A 380-480V, 3-Phase IEC 60309 3P+N+E IP67 connection to data center power. |

| Cooling Design | Direct Water Cooling at the heat source with treated clean water supporting inlet temperature from dew point to up to 45°C. Servers connected through blind mate quick disconnect to manifold in Enclosure. Each enclosure providing an Inlet and an Outlet connection with dual-interlock FD83 ball valve. |

| Limited Warranty | 3-year customer replaceable unit and onsite limited warranty; Next business day 9 to 5; Service extensions and upgrades available |

- Details

- Written by: J C Burke

- Hits: 3480

Bio-Methane is simply methane generated from organic wastes {in an oxygen starved environment}. Methane capture from coal mines, and methane from other sources {such as tapping into waste-dumps} is a welcome strategy to utilise the enormous amount of waste, we produce. Estimated at 105bn tonnes globally by the World Bio-Gas Association {see article re -methane here on new tab - close to return here}.

Bio-Methane is simply methane generated from organic wastes {in an oxygen starved environment}. Methane capture from coal mines, and methane from other sources {such as tapping into waste-dumps} is a welcome strategy to utilise the enormous amount of waste, we produce. Estimated at 105bn tonnes globally by the World Bio-Gas Association {see article re -methane here on new tab - close to return here}.

However, it is perfectly OK to use methane from oil/gas exploration too - and with the UK's highly extensive gas grid, its all carried together to provide primary energy. Energy that is easily stored. Unlike that secondary energy source - electricity - which we will discuss further later.

But CHP? Combined Heat AND Power {and sometimes cooling}

We have tried to introduce CHP previously, as an important and strategic alternative to Centralised Electricity Generation. There are major disadvantages with centralised generation;

- Inefficiency discussed previously here {click} and again here {click} and cooling towers explained here {click}

- Instability

- Storage Problems

- Supply to Match Demand Problems Nationally

- Details

- Written by: J C Burke

- Hits: 6366

Introduction:

Introduction:

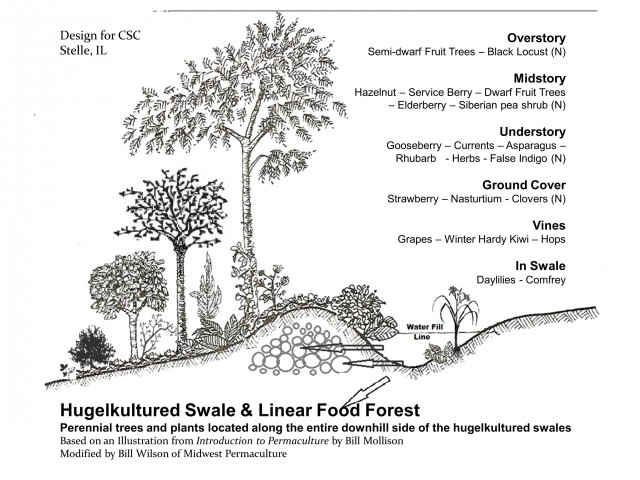

"Permaculture" is an agricultural and social design system that is centred around creating sustainable and regenerative human habitats. The term "permaculture" was coined in the 1970’s by Bill Mollison and David Holmgren in Australia, who saw the need for a more sustainable approach to agriculture and human habitation. However this concept has been demonstrated in many places around the World. Geoff Lawton, another great proponent of Permaculture, stumbled upon a 2000 year old example in Morocco, near the tiny village of INRAREN. Geoff, who was only 21 at the time, explains:

"The air felt cool, almost misty. Growing in the shade of tall date palms were trees, vines, and shrubs bearing bananas, tamarinds, oranges, figs, guavas, pomegranates, lemons, limes, mulberries, carobs, quince, grapes, and other fruits and nuts. Following a footpath through the grassy understory past groves of olive and argan trees, Lawton discovered a cluster of fenced-in vegetable and herb gardens—most about a quarter-acre in size."

"Here and there, goats were tethered to posts. Chickens clucked through the underbrush and roosted in trees. Gazing down a leafy corridor, he spotted a man leading a donkey. Its saddlebags brimmed with produce."

Regarding what Goeff had found all those years ago: Totaling about 65 acres, the food forest was a remnant of one of the world’s oldest sustainable systems of agriculture. While its origins have been lost to history, scientists agree it is at least many centuries old. Some, including Lawton, date its establishment to 2,000 years ago. When asked about the forest’s age, villagers shrug.

“I have no idea how old it is or when our ancestors first began gardening here,” says 45-year-old Abdelmajid Ziyani, a construction worker and member of a local argan and olive oil cooperative. “But I know it has been here for centuries.”

“I have no idea how old it is or when our ancestors first began gardening here,” says 45-year-old Abdelmajid Ziyani, a construction worker and member of a local argan and olive oil cooperative. “But I know it has been here for centuries.”

“It is really old,” adds 28-year-old Brahim Jidi, with a laugh. He works as a waiter in a local hotel and gardens in the forest as a hobby. He says he grew up hearing stories about his “grand- grand-grandfather” helping tend the forest.

In the 1970s, the communal space was “farmed” by about 800 villagers. Fed by underground springs and shaped by human hands since time immemorial, it was the image of a true oasis. The system remains in use today.

Now 65, Lawton describes his experience at Inraren as life changing, and he has spent a career growing food forests and advocating for their importance as a solution to climate change and other environmental ills. But back in 1975, his friends were threatening to leave him in the woods. Snagging a few oranges, he split. By the time the group reached Paradise Valley, the forest seemed like ancient news.

Permaculture has since become a worldwide movement, with practitioners in over 120 countries. This research paper explores the principles and design aspects of permaculture, including its history, philosophy, and practical applications. Permaculture is a sustainable design system that provides a practical and ethical approach to land use, agriculture, and community-building. It aims to create a harmonious relationship between humans and nature by using principles that focus on working with natural ecosystems. The following research paper explores the principles and design aspects of permaculture and the benefits it offers for sustainable living.

- Details

- Written by: J C Burke

- Hits: 33164

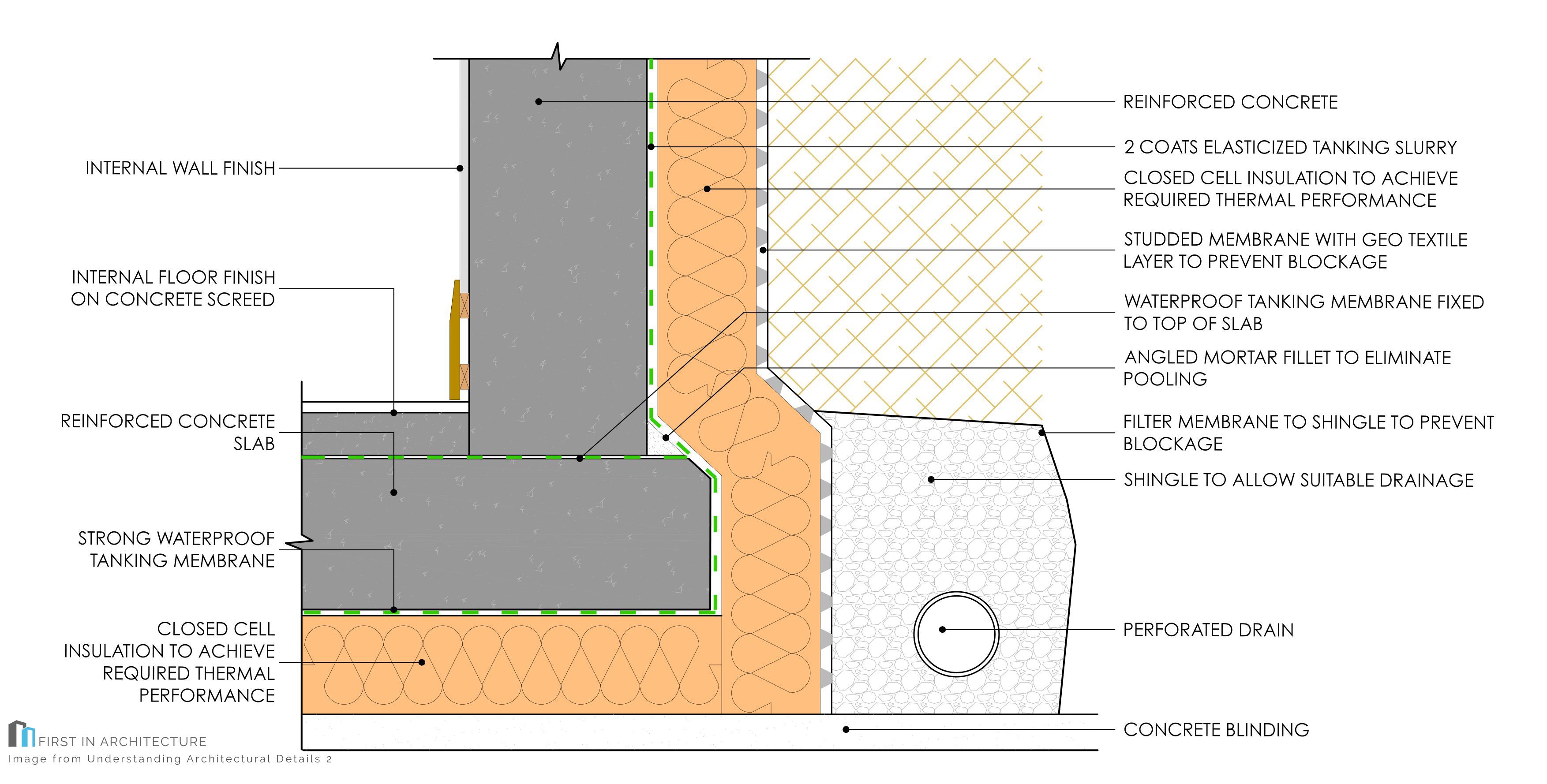

Basements for housing

Including a basement in residential developments helps maximises usage of available land, offers added value, more space and accommodation with additional performance benefits. Refurbishment or alterations to existing spaces below ground are also an effective way of providing additional habitable space to a property. It is possible to retrofit a basement under or adjacent to an existing property.

A basement story is defined within the Building Regulations of England and Wales as at least 1.2m below adjoining ground level. This aspect has implications for natural lighting and ventilation. For much deeper structures there are several other options to cover there two important issues.

Benefits of domestic basements include:

- Added value.

- Additional habitable or useful space.

- Increased floor area in locations with limited development potential above ground.

- Creation of flexible, adaptable space, due to creation of single span structure.

- Spaces with extra sound insulation, expanding range of potential use, including home working, home cinema or wine cellar!

- Spaces with good thermal mass and potential energy efficiency and cooling.

- Good stable structural base, capable of supporting heavy loads above.

- Resilience to local environmental effects in the soil, such as shrinkage or tree roots.

- Flood resilience solution, by raising habitable spaces above flood level while providing useful non-habitable storage space below.

Basement design

The appropriate design of basements is well established and achievable providing design and construction guidance is implemented.

Basement design process simplified:

- Establish current and anticipated future use of basement.

- Site survey and soils analysis including exploratory works.

- Design proposals to define type of construction water tight class, ventilation and thermal performances.

- Detailed structural design integrated with design of waterproofing/drainage.

- Utilities entry, Earth Pipes etc and construction waterproofing, detailing etc

Aspects of the design process are interrelated and a unified approach should be established defining roles and responsibilities of the design team. It is advisable to avoid complex geometries to facilitate waterproofing and to produce a three dimensional review of structure and waterproofing.

Basement construction

Reinforced Concrete is the most common and appropriate material used in the construction of new basement walls and floors. This is due in part to cost and availability but also its adaptability, inherent resistance to water, durability underground and ability to provide a stable structural surface for the support of waterproofing membranes. Options include masonry or blockwork, cast insitu, precast concrete, twinwall and insulating concrete formwork (ICF). The graphic shown has an insulated layer on the outside of the basement wall - however most practical is Insulated Concrete Formwork [ICF]

The method of concrete construction chosen will be influenced by the type of waterproofing protection permitted according to the water table situation and proposed basement use as described in BS8102 Code of Practice for the protection of below ground structures against water from the ground.

For further guidance on the benefits of basements for housing and principles of construction and design refer to Basements for Housing.

The publication ‘Concrete Basements: Guidance on the design and construction of in-situ concrete basement structures’ provides comprehensive guidance on the design issues for the design of deep basements, focusing on structural calculations.

Other useful resources: